Q1 2025 OSHA Regulatory and Safety Bulletin: Key Updates for Contractors and Safety Professionals The…

Safety in Construction: Insights, tips and strategies from safety leaders

Safety in Construction: Insights, tips and strategies from safety leaders

Demand for new workers in construction looms large: The industry needs an estimated 439,000 net new workers this year, and it will need even more in 2026, according to estimates from the Associated Builders and Contractors.

That creates a conundrum for overseers of safety, a term that today carries a broader meaning and value across work sites. Construction companies desperately need new workers, but they don’t want to sacrifice valuable safety gains.

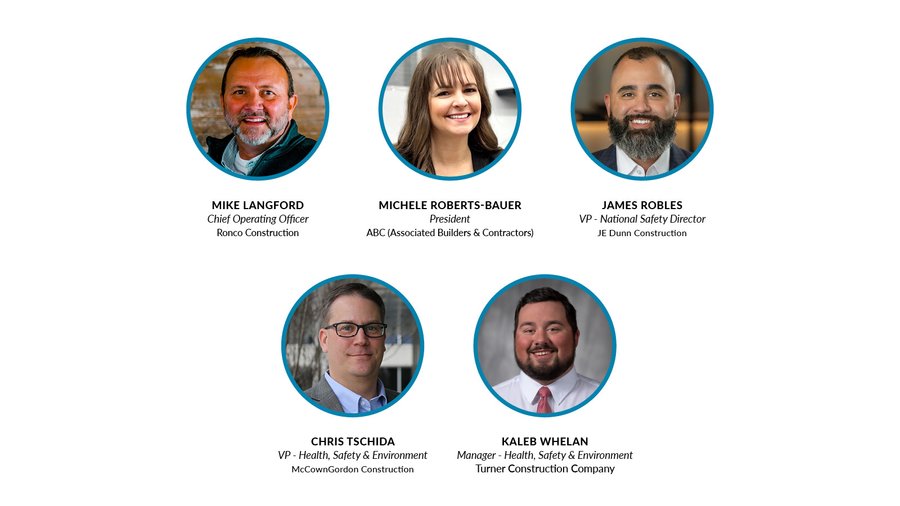

The Kansas City Business Journal recently gathered leaders of safety considerations for area construction companies to discuss these challenges. Sales Director Melanie Clark guided them in a conversation about how — and why — they establish cultures of safety, about technology and planning tools that further safety goals, and about measures to encompass mental health as an integral part of safety.

MELANIE CLARK of the Kansas City Business Journal: What’s your favorite thing about being in safety, and what really stands out?

MICHELE ROBERTS-BAUER of Associated Builders and Contractors, Heart of America Chapter: Safety is the thing you do that has a direct impact on the well-being of your people. Establishing a strong safety culture and empowering people to make safe, healthy decisions impacts them at work and at home, and I would argue it’s one of the most important things we do for our people.

MIKE LANGFORD of Ronco Construction: At the root of it, all of us care about people. If you care about people, you want them to go home to their family and friends every single day. We have a unique opportunity in safety to impact people’s lives and improve people’s lives, and not just from a monetary standpoint. Everybody’s got to have a job; everybody’s got to support their family. But we have an opportunity from a day-to-day aspect, from a mental health aspect, from a physical health aspect, to really impact people.

CLARK: What are the current safety challenges?

JAMES ROBLES of JE Dunn Construction: We’re in a good position where there’s plenty of work to go around, but getting the right people out there to build it is the challenge. That’s been a pretty heavy topic the last couple years.

CHRIS TSCHIDA of McCownGordon Construction: Currently, I feel the industry is dealing with a few. First, we need to find people to fill the roles needed and who want to join the industry. Second, we have to assess their skill set and experience. We also know we will need to help train and educate them based on their role within the organization and potential hazards they could face. Some individuals may be coming in brand new, and with that, we have a clean slate from which to build. At McCownGordon, we’re working with our field craft to create a more robust onboarding process to ensure a certain level of knowledge and skill from the start.

KALEB WHELAN of Turner Construction: We fight that struggle, and you also fight a struggle with people that have been doing it for 30 years, and you’re trying to change a mindset. That can be just as challenging at times. So it’s a knowledge gap that we have to get through, and it’s coaching, and it’s giving people the ‘why’ and helping them through that process.

CLARK: Do you feel like there are enough resources out there for building the workforce, or do you feel there are substantial gaps?

LANGFORD: I believe there are plenty of resources. I think the problem is finding the people that are motivated to want to get into this industry. (Twenty years ago), during the last recession, we really started losing our tenured workforce to either retirement or choosing different trades. … It’s just getting the student counts up is what we really need. We need kids to want to come into the trades.

ROBERTS-BAUER: We need time. Construction is a combination of art and science, and there are things that you can learn in the classroom about the theory, but to perfect the art — to have the wisdom to do things effectively and do it effectively the first time, and within a reasonable time frame — you can’t teach that overnight. These are skilled trades that take years to perfect. And the problem is, you can’t just bring somebody in — I don’t care what their work ethic is or how smart they are — you can’t turn them into a journey-level or master-craft professional overnight. We need time.

LANGFORD: We’re starting to target not only the high schools, but the junior highs, trying to get the industrial arts programs back, to get the hands-on, fun things at these career fairs at such a young age to get them to spark that interest.

TSCHIDA: As an industry, we need to be able to answer the question of, “Why construction?” We also need to show the benefits of joining this ever-changing industry — not view it as a fallback. By showing that a career in construction is an honest-to-goodness way to make a great living, with very competitive pay and benefits, we can hopefully begin to see a change for the better.

ROBERTS-BAUER: We’re seeing that shift here in the Kansas City metro. The requests that we get to go to career fairs in the high schools, to meet with high school students, to tell the story about the career opportunities — it’s night and day from what it was 10 years ago, and I think that people are really starting to see that career pathway.

CLARK: Bringing it back to safety specifically, how do you make safety not just a priority, but a commitment?

ROBLES: It has to be owned from the top. If you get the leaders involved, then if it matters to the boss, it matters to them — but it has to be genuine. That’s the other component. It can’t just be a poster on the wall or an email that goes out. It has to be true ownership from the top down, and engagement as well.

LANGFORD: I would echo that, James. It’s leadership presence, and then it’s safety by influence, not just instruction.

WHELAN: Ownership almost creates accountability in and of itself. When we set the hard line from a leadership perspective, and we say we will not take the chance of hurting somebody to meet a schedule or to save a buck, then that makes its way down to your foreman and your general foreman, and they really own that crew and own that process, from the pre-planning all the way through the execution of the work. That’s where you see that shift. And I don’t think you can force it, but you have to put the right people there leading and running your crews. Sometimes even the best, fastest people out there getting the work done are not always the right people to have in that position. And sometimes you’ve got to make that hard call. People see that, and that creates a culture, and it spreads from there.

TSCHIDA: I think it starts with leadership, but the next step is getting to the “why.” We need to have people internalize it, make it important to them. Everyone has a “why do I work safe” reason — family, friends, loved ones. When something is that important, it helps to make decisions easier. People will take less risk to ensure they go home safe and whole each night. By making it personal, we can get that commitment.

CLARK: When it comes to training requirements, what content do you have for your employees when they come? What seems to be the top-performing training that you use, and what would you like to see expanded upon?

ROBLES: One of the things we made mandatory here a few years ago was the safety culture training, no matter if you’re in our office or out in the field. That way, we set the expectation up front. It’s easy to understand when it comes from the beginning: This is what they expect of me, and this is how I’m going to perform, regardless of what my title is. It sends the message that safety is important.

WHELAN: We do a lot of culture training, but a lot of that comes from a field leadership standpoint, as well. It’s training on how we expect the culture to be on our projects, and on how we want you to promote, on leadership techniques, on how to accept feedback and understand how they can promote themselves up through the ranks, and on how to encourage the people around them to perform better on a day-to-day basis. That, for us, has been a good shift. You can provide all the statistical, fact-based things that you want and tell them how to perform the work safely, but at the end of the day, if they aren’t pushing it when one’s looking, it doesn’t matter.

LANGFORD: From the first day of onboarding, our first four hours is 100 percent safety and culture, regardless of the silo or the discipline — whether you’re accounting, IT, operations, it doesn’t matter. You’re going to spend that time so that they see how important it is for us in that culture. We really want people to see that it’s a peer-driven accountability, where our culture empowers everyone to see something, say something — not wait.

CLARK: What are the key technologies that you are using to enhance safety?

LANGFORD: I’ve been in this industry a very, very long time, and the evolution of the apps has really been the funnest part for me. We’ve been working with app developers to find the one that allows us to be a one-stop-shop of information in all disciplines for our company, but the No. 1 priority for that app is real-time awareness — for weather, for site updates, for if you see a near miss — anything that we can blast to all of our employees in a matter of seconds.

WHELAN: We have a permitting process where we can make our permits electronic, and it streamlines that process. People are more likely to do it if it’s easier to access and easier to put in place. So we’re utilizing a lot of those apps for our permitting process, for delivery logs, for site updates, foremen can create separate chats for which area they’re working in. It really streamlines a lot of the stuff that we do. People don’t want to do something that slows them down at the end of the day, when they have so much stuff they already feel is piled on their plates. So anything that we can do to streamline that process, from a field aspect, is fantastic. We’re continuing to look for things like that where we can still get the exact information out there that we’re looking for, but almost in a better way. AI is something we’re trying right now. It’ll actually pull information out of all of those manuals and tell you exactly what expectations are.

LANGFORD: When we went with the app last year, tornadoes rolled through the Omaha area, and we were able to send out a push notification for everyone to take shelter. Two and a half, three minutes later, the tornadoes went through — no injuries, no loss of life.

ROBERTS-BAUER: I have been impressed regularly with how AI and technology is coming in and impacting the industry. Even very small companies can use these tools to improve their communications with their team members. One of my members last week was showing me that they can upload safety notes and elements of their safety manual and put together a podcast to deliver to all of their team members at no cost. It’s free. There is no financial barrier to taking advantage of these things and getting this information out in a repetitive way where people can continue to listen. It’s incredibly accessible now, and to the point of ease of use, something that’s easy gets done.

ROBLES: In construction, not a whole lot of things change. But this is an exciting time where we can leverage AI, and also match that up with the seasoned folks that have been here 30, 40 years, and combine both, and pretty much eliminate most risks that we can face on a project.

CLARK: How are your companies integrating safety in the early stages of a project?

ROBLES: One of the things that we do well is meeting with the clients, ensuring that we understand what their expectations are. And not only the clients, but our operators that are going to be building the project, and our trade partners that are going to be involved with that project, because having all those different levels of insight helps us align on what the expectations are from the get-go, before that first shovel hits the ground.

TSCHIDA: At McCownGordon, we start by looking at each project from a risk perspective — is the risk of this project a good fit for our company? If it is a go, then we start to pre-plan in several phases very early on in the process — the right team, project logistics planning, schedule planning, risk mitigation plans, and the list goes on. Once a project is won, we have to formulate the right plan to deliver the project to our client on time, on budget, and done safely.

LANGFORD: We always tell everyone that 90% of the success of every project starts before we ever put a shovel in the ground.

WHELAN: I think the industry started to shift that way a little bit too, as people are seeing the benefit of the pre-planning process — of being more selective with your contractors that you’re bringing in and basing it on safety performance in addition to field performance. And then going to owners and getting them to buy into the culture that you’re providing on the project, and really selling to them that this needs to be a project where people want to come to work every day, not a project where people feel like they have to show up. That’s how you’re going to get the best people and the best performers out there. Sometimes there are extra dollars in a project — providing the heating and cooled restrooms and a nice tent or facility for them to have lunch in every day. It may seem simple for those of us that work on the other side of it, but for the guys in the field, that’s something that shows we care.

One thing that we’ve really started to run with here recently is reviewing the job hazard analysis (JHA) with the foremen that are going to be running the crews, in addition to their leadership, before every single scope of work that goes into place in the field. It’s a 20- to 30-minute meeting if the JHA looks good ahead of time. But what we were seeing is that we spend so much time on high-risk activities, and we put so much planning into them, and then where are we seeing our injuries? Well, we’re seeing it in the little smaller tasks that nobody’s really paying attention to. So why don’t we put a little bit more attention on those things as well, on the front end? And we’ve seen a tremendous amount of success in doing that. It takes people’s time on the front end and a little bit of effort, but it pays dividends on the back end.

CLARK: The next large topic is mental health and the total human health impact. How are you implementing this, and how are you seeing progress when it comes to mental health on site?

ROBERTS-BAUER: It’s been a huge initiative. Maybe seven, eight years ago, you started hearing about mental health and construction, and it’s my firm belief that COVID really sped that process up. All of a sudden, people couldn’t deny what was happening around them. I have been amazed and pleasantly surprised by the contractors embracing mental health resources for their team members. For all of the stigma, for all of the ‘buck-up, buttercup’ mentality that’s out there, I don’t think contractors needed to be told we had a problem. I think they knew we had a problem and didn’t know how to articulate it, because the responsiveness has been absolutely incredible as we have rolled out resources and worked to empower our people to take a proactive approach to doing something about it.

WHELAN: What really opened my eyes was when we started putting psychiatrists on some of our larger projects. We started with, like, four hours a week, and all of a sudden that got booked. And then we did a full day. And all of a sudden we’ve got some projects with 40 hours a week of mental health professionals that are booked out from Monday through Friday. We put so much effort into the safety side of it, from a physical putting-work-in-place standpoint. But we’ve got five times the amount of people that are losing their lives in the construction industry every year to mental health battles versus putting work in place in the field. We’re going to have to shift the industry and start putting the same amount of effort into mental health.

TSCHIDA: This topic has been long overdue in our industry. For years, this was almost taboo to talk about, but the need is definitely there. Most companies have recognized this and have plans in place to address it. We have started a peer support program to help our projects, associates and trade partners. We identified several associates throughout the organization that have been trained to identify signs of issues, listen, and assist with getting those in need with the proper people to help their mental health. At the end of the day, this is simply being empathetic, and it’s people helping people.

ROBERTS-BAUER: We have a suicide prevention course for the construction industry through VitalCog that a lot of companies have accessed. It’s an incredible two-hour training, and I have been delivering it to all of our apprentices this year. We have almost 400 apprentices; we’ll do all of them this year, then we’ll do it with first-years moving forward. I was fully prepared for attitude and eye-rolling and disengagement in the classes. But the conversations that have come out of, literally, a two-hour training have been some of the most important in my career.

ROBLES: I think the COVID era did bring that up into the light. It was unavoidable, like Michele said, but the biggest step forward that we made as an industry, and in a lot of the general contractors I know, was that we could just have the conversation. At JE Dunn we utilize Lyra, which provides mental health resources for our employees. It’s important that we talk about it and go through these trainings, so it’s not taboo to talk about it anymore. You just never know what people are going through.

LANGFORD: We use the Methodist Health System Program for Employee Assistance the Methodist program for our employee assistance, and we also expanded that to any family member of an employee. Now, we’ll open that up to our trade partners as well, because it’s such an inexpensive service with a long term ROI for everyone.

CLARK: Through navigating these challenges, what lessons have you learned?

ROBERTS-BAUER: The need was there. We just weren’t ready to deal with it. You don’t have to convince people that the need is there. They know — they’ve experienced it.

WHELAN: I think the biggest thing that I’m learning through doing this is that we have a long way to go. We’re just at the precipice of this and learning how to navigate it ourselves. This is the group that has got to push the rest of the industry to get there. And we’re going to have to continue to figure it out as we go, and continue to push the bar.

TSCHIDA: I think every year it’s getting a little easier to have these conversations around mental health. The more consistent we stay with these topics, the more people will be comfortable discussing — that’s a huge step. If we can help even one person, that’s still one person with family and friends that need them.

CLARK: Wrapping it up, what are the focus areas for the next few years?

ROBLES: Working on the people, making sure that they’re prepared for the future. It’s finding those that are willing and open to join this great industry, but also making sure that they can grow and develop into the future leaders that we need. Because not not only do we need people, we also need good leaders. If you have that, then your company will be safe and successful.

TSCHIDA: This industry is about people — finding the right people to join your organization, and then training, supporting and growing them in their careers. We need to develop our future leaders in more than just skill-based training. We need to focus on leadership and management style training to help them develop others. This is how we build the next generation of construction professionals and ensure our industry thrives for years to come.

ROBERTS-BAUER: I think so much of this, whether it’s safety or being more innovative, it’s leadership — it’s establishing the culture of how we’re going to get the job done, and how we’re going to treat each other while we’re at it. Our handshake means something.

WHELAN: A big focus area for us right now is consistency of those messages and caring about people. And we’re meeting with the smaller companies and the sub-tiers, and our trade partners that are working with us. On projects that last five, 10 years, you see these companies come in and develop a culture, and they take a lot of things with them, and all of a sudden they’re changing their own company’s culture. So how do we create that same thing on the jobs where they’re only there for six months or eight months or a year, and take it with them when they go? So we’re meeting with a lot of them and sitting down with them and offering resources. We want you to leave this job and go to your next job, and continue to do it safely, because that is your company’s expectation, not because Turner makes you do it when you are on their job.